Exploring factory waste.

Ten years ago I was able to visit and work with a number of textile factories, it was very clear that there is an awful

lot of waste as over runs, off cuts and rejects in the garment and textile industry.

In observing this, I wanted to explore the possibility of trying to gather and use up as much waste fabric as possible without investing too much energy into the repurposing and stitching together of scraps.

My mind was drawn towards the way a receipt spike efficiently archives scrumpled up paper transactions by skewering them side by side in a rapid, spontaneous and direct manner; paradoxically ordered but in a rather haphazard and disorganised way.

The spike acting as a fixed needle that is constantly ready to pierce, but in this instance also provide the structure as more receipts pile up; likewise this orderly disorder could be the perfect way to gather, impale and consume lots and lots of textile waste. An image of factory waste at a textiles and garment factory.

An image of factory waste at a textiles and garment factory.

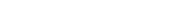

A sturdy solid oak stackable chair frame is formed from a uniform square section of timber. Ebonised black to maintain a graphic linear outline that is essentially the cradle for the scrap fabric, pierced and stitched through by "Kintsugi-esque" golden brass and steel hardware.

A sturdy solid oak stackable chair frame is formed from a uniform square section of timber. Ebonised black to maintain a graphic linear outline that is essentially the cradle for the scrap fabric, pierced and stitched through by "Kintsugi-esque" golden brass and steel hardware.

Kintsugi is the Japanese art of repairing broken pottery with golden powder lacquered into the glue and cracks. This is part of the broader philosophy of "wabi-sabi" which celebrates the imperfect nature of things as beautiful and meaningful. The golden brass hardware is therefore the perfect "stitch" to join and skewer together the discarded scraps of fabric waste and bring them a new lease of life. A simple carton template is made as a shape to follow whilst cutting the fabric; the metal skewers are aligned with the template so the holes are in exactly the correct spot.

A simple carton template is made as a shape to follow whilst cutting the fabric; the metal skewers are aligned with the template so the holes are in exactly the correct spot.

The naked oak frame is stitched with the brass and steel hardware, ready to kebab the scrap fabric.

The naked oak frame is stitched with the brass and steel hardware, ready to kebab the scrap fabric.

Bags of scrap cotton, linen, denim and many more types of fabrics are brought to the cutting area where they are sorted and piled up ready for slicing into shape.

Bags of scrap cotton, linen, denim and many more types of fabrics are brought to the cutting area where they are sorted and piled up ready for slicing into shape.

The sorting process was mainly decided by keeping the offcuts of similar fabrics side by side the same to maintain various pleasing dense blocks of similar colours and textures.

For future production, the selection will be delegated to the factory workers to choose, pile and order based on a simple formula of maintaining blocks of colour at least 1 - 2cm thick, albeit they will be different each time in just the same way our Upcycled Marble Tables are made with the scrap marble and granite from the tradespeople and masons.

Working directly at the garment factory I was amazed by the cutting power of these incredible slicing machines and the deftness of the workers that handle them. I believe this knife could easily have cut double the thickness without much effort, leaving a very satisfying clean edge.

Working directly at the garment factory I was amazed by the cutting power of these incredible slicing machines and the deftness of the workers that handle them. I believe this knife could easily have cut double the thickness without much effort, leaving a very satisfying clean edge.

Whilst the edges were indeed cut clean, there is no further hemming or stitching to the cut fabric, I very much like the raw, frayed edges with loose threads dangling down. The amount of fabric skewered between the oak frame means the fabric will remain compressed and dense despite the fraying edges so the small scraps do not have a chance to disintegrate or unravel too much beyond some wiry loose ends.

Punching the holes for the skewers couldn't have been easier with the use of a very sharp hole punch, thick rubber mat and a trusty hammer!

Punching the holes for the skewers couldn't have been easier with the use of a very sharp hole punch, thick rubber mat and a trusty hammer! Whilst we aligned the scraps carefully with the templates, it was reassuring that the flexible nature of the fabric allowed for some gentle stretching and manipulation to precisely locate each skewer.

Whilst we aligned the scraps carefully with the templates, it was reassuring that the flexible nature of the fabric allowed for some gentle stretching and manipulation to precisely locate each skewer.

The completed Scrap Fabric Chair. After cutting, punching and skewering thousands of waste scraps that would have otherwise gone to the incinerator or landfill. Factories often have to pay a tax by the weight (kg bags) of waste that they throw out. The idea behind this chair was to use up any kind of fabric, which means each chair will be unique and after many factory visits, there should be no shortage in the yield of textile waste!The Scrap Fabric Chair photographed on a work table within the sampling room of a garment factory.

Each chair will be unique, based on the waste fabric that is available at the time of production. Even within a set of 6 - 8 chairs around a table, there will be absolute uniqueness, whilst production will be made to match relative to the batches of waste at time of production; this is also why the chair frame is kept to the simple graphic black line to provide some uniformity amongst the varying livery of the colourful scraps.

Each chair will be unique, based on the waste fabric that is available at the time of production. Even within a set of 6 - 8 chairs around a table, there will be absolute uniqueness, whilst production will be made to match relative to the batches of waste at time of production; this is also why the chair frame is kept to the simple graphic black line to provide some uniformity amongst the varying livery of the colourful scraps.

Some close up images show the tightly packed scraps with their fuzzy frayed edges. The simple stepped design of the chair with back legs that span over the sides and front legs allow for the chair to be stacked. The scrap fabric hangs down below the frame, rather like a wiry Billy goats gruff beard.

The scrap fabric hangs down below the frame, rather like a wiry Billy goats gruff beard.

The angle of the seat and rake of the back rest allow for a nice comfortable seating posture.

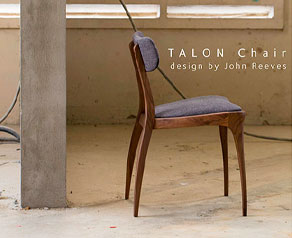

The angle of the seat and rake of the back rest allow for a nice comfortable seating posture. My technical assistant Mr Loi and John Reeves testing the Scrap Fabric Chair.

My technical assistant Mr Loi and John Reeves testing the Scrap Fabric Chair.

The Scrap Fabric Chair was conceptualised and sampled over 10 years ago, however we did not have the opportunity to bring it to market and launch.

However, I believe it is more than just an exploration in waste management and indeed those that have seen this chair and understand the project behind it have shown encouraging interest. I whole heartedly believe it should be a viable product with implications on how we consider form and aesthetic whilst utilising waste in a functional, fun and challenging way.

I think designers should have a duty to discover and rediscover waste from industry in any sector and consider how best to implement these resources to good and functional use.

Reeves Design strives to engage a strong narrative with each one of our designs and collections and I believe more than ever, our customers, the design community and even the world at large is open to appreciate a more considered purchase.

I would like to ask you to take a moment and engage in response by hitting reply to this newsletter with your thoughts on whether we should pursue this chair further into production or not?

Yes or No?

"I hope you continue to enjoy receiving the Reeves Design newsletter which has always intended to be a window into the inspirations that go into each design.

I encourage you to reach out with any projects and ideas that may align with our values and vision so that we can continue to develop the Reeves collections and ensure they find the right homes.